Anti-Fouling Delf-Cleaning CoatingAnti-Fouling Delf-Cleaning Coating

TGA1096 Dust-proof, Anti-Reflection And Wear-Resistant Nano Self-Cleaning Coating

【Product Manual】

Product Description

TGA1096 dust-proof, anti-reflection and wear-resistant nano-self-cleaning coating is a special one-component inorganic

nano-coating developed by TGA, which is self-drying at room temperature and free from dust, pollution and anti-reflection.

Self-cleaning, dust-free, antistatic, anti-reflection and anti-pollution design is used for self-cleaning anti-reflection and

anti-dust treatment of photovoltaic glass, solar photovoltaic and other products. TGA1096 adopts the latest nano-silica

fractal combination technology, which can form fine concavities and convexities below 50nm on the surface of the object,

and the cured ultra-thin coating has a hydrophilic angle of less than 10. Pure inorganic components, the coating has

superior weather resistance and wear resistance, and the coating can inhibit the generation of static electricity on the

surface of the substrate at the same time, making it difficult for dust to adhere to the substrate. Even if the attached dust

cleans itself when it meets water, it always maintains the light transmittance and cleanliness of the photovoltaic glass surface,

reduces the efficiency attenuation of crystalline silicon photovoltaic modules, and improves the average power generation

gain of conventional modules by 2.8-3.25%.

Product Features

Ø Quick-drying at room temperature, it can be dried in 1-5 minutes, and it takes 24 hours to completely cure, and the

hardness is more than 4 hours (Mitsubishi pencil, Japan)

Ø Compared with the traditional superhydrophilic coating with a wear life of 1000 times, this product has a wear life of

more than 15000 times, pure inorganic components, excellent weather resistance and protective effect of more than 3 years.

Ø Super antistatic and wear-resistant performance, the surface resistance value is between 106 and 109 Ω, which greatly

reduces dust adhesion.

Ø High transparency, low reflectivity and remarkable anti-reflection. After construction, the glass reflectivity of photovoltaic

module is reduced to 0.6-1.0, and the power generation is increased by more than 3%.

Ø Remarkable anti-reflection, after construction, the reflectivity of photovoltaic panel is reduced to 0.6-1.0.

Ø If the water contact angle is less than 10, dust or stains on the self-cleaning surface will be exposed to rain or condensation,

which will reduce the cleaning frequency.

Recommended Use

u Self-cleaning and dust-proof treatment of centralized photovoltaic power station.

u Self-cleaning and dust-proof treatment of distributed photovoltaic modules.

Pre-construction treatment and matters needing attention

A. Judge the surface state of photovoltaic glass before scraping: wash the surface with clear water, if the surface presents

a hydrophilic film, it is considered that there is no oily dirt and no residual antireflection film on the surface, and scraping

construction can be carried out directly after dust removal and ash removal with clear water;

B. If there is slight shrinkage, the special multifunctional cleaning agent for photovoltaic glass can be diluted with water

according to the ratio of 1: 10, and then cleaned. If the shrinkage is serious, it proves that there is still a residual antireflection

film. In order to improve the adhesion, it is suggested to spray it directly on the surface with a multifunctional cleaning agent

special for photovoltaic glass, wait for 30 seconds -1 minute, treat it with special cleaning equipment for photovoltaic glass,

and then rinse it with clear water.

C. The cleaned surface should be scraped and coated in time to prevent dust from coming back.

D. The cleaned surface should be scraped and coated in time to prevent dust from coming back.

E. Avoid construction when it rains.

Construction Method

1. Use special construction equipment for scraping and coating.

2.Be able to construct 2000 square meters for the manpower per four people/set/day.And be able to construct 5000 square

meters one per four people/day for the robot.

3. One-time treatment, valid for 3 years.

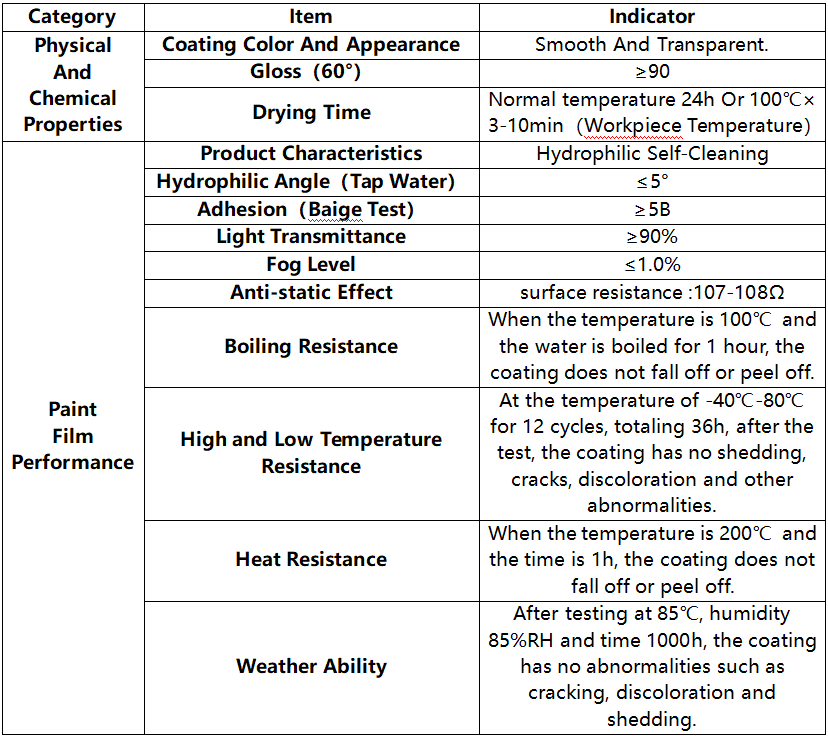

Technical Parameter

Curing mode

Self-drying at normal temperature, standing for 24 hours and completely curing.

Storage mode

Suggested storage temperature: 18~25℃

Service life: 6 months

Product Health And Safety Information

Please refer to the latest version of the product technical safety technical instruction manual (MSDS) of Aochang Company for information and suggestions on product operation,

storage and disposal. It includes product physical characteristics, ecological, toxicological data and other related safety information data.

Statement of good faith

TGA promises that all the product data listed above are obtained by testing in relevant laboratories according to corresponding standards. During the test, the relevant data will be

slightly different due to the different test environment and methods. Therefore, TGA company advises customers to do experimental demonstration before using the product. Except

for the product quality itself, TGA Company assumes no responsibility and reserves the right to adjust and update the above data without prior notice.

简体中文

简体中文 English

English