Energy-Saving Thermal Insulation CoatingEnergy-Saving Thermal Insulation Coating

Active Practitioner Of Green Environmental Protection And Energy-saving Products

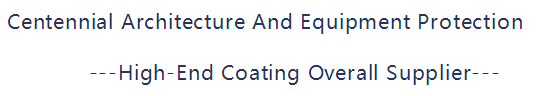

TGA®Poly-Asparagus Silver Heat Insulation Energy-saving Anticorrosive Coatings

★Waterproof and Anticorrosion ★Wear protection ★Anti-fouling Self-cleaning ★Heat Insulating ★Fire and Flame Retardan

TGA®Poly-Asparagus Silver Heat Insulation Energy-saving Anticorrosive Coatings

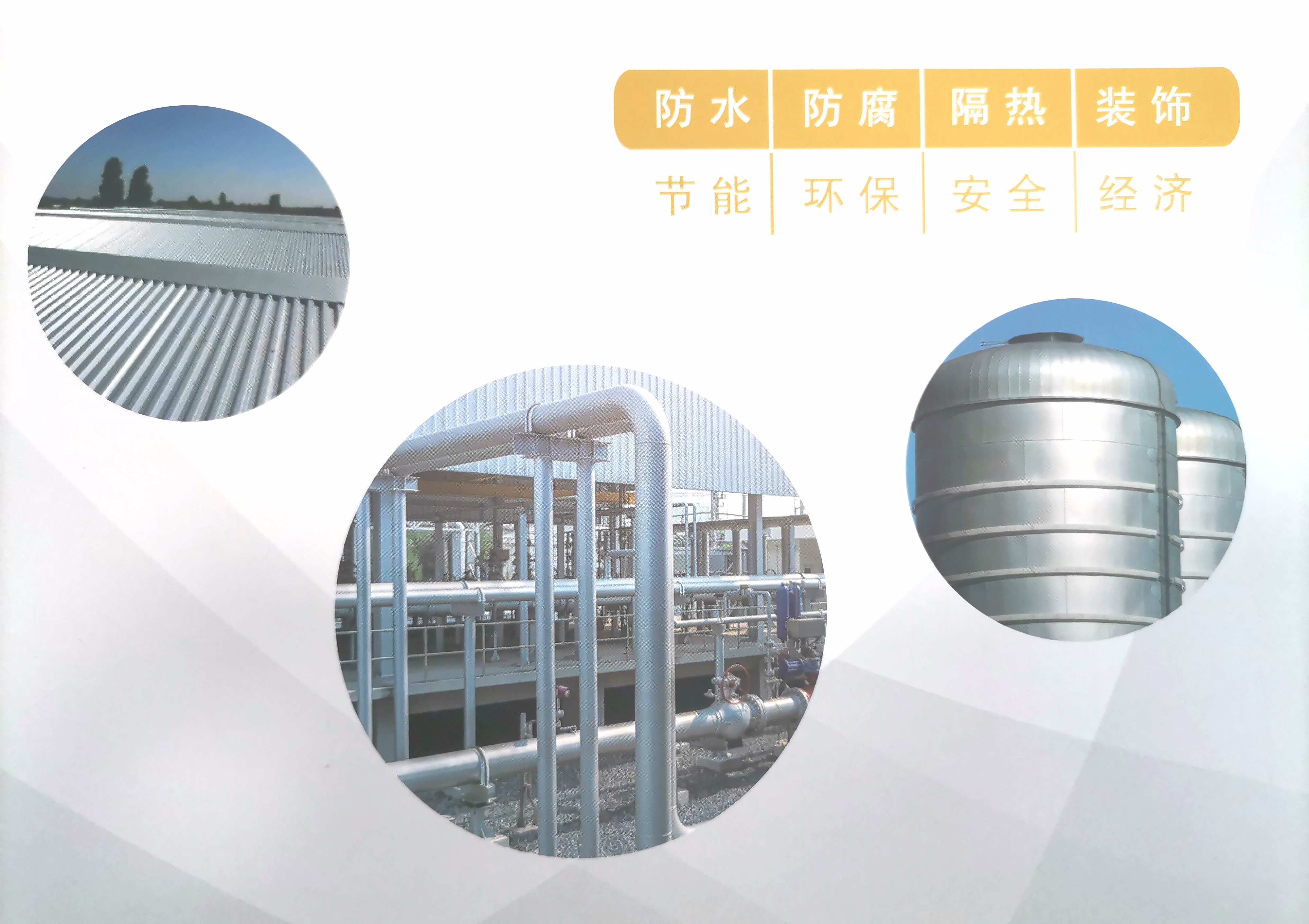

1、Waterproof And Anticorrosion

TGA® Poly-Asparagus Thermal Insulation Waterproof and Anticorrosive Coating is a kind of waterproof and anticorrosive thermal insulation coating with high

performance and long service life. The selected silver metal material is shiny flake, which can effectively reflect light and thermal radiation, achieve the effect

of cooling and saving energy, and make the living environment more comfortable. The metal sheets in the coating are overlapped from bottom to top, which

can prevent electrostatic accumulation and meet the requirements of safe production in the chemical industry.

2、Energy Saving And Heat Insulation

After nearly 10 years of research and development and continuous innovation, TGA® has successfully developed the principle of "8~13.5μm atmospheric

infrared window" to realize radiation heat transfer in specific infrared bands, and achieve the purpose of overall metal insulation by reducing the heat flux density

of metal structures. TGA® poly-Asparagus metal thermal insulation energy-saving anticorrosive coating, and all performance indexes of the coating are superior

to the standard of traditional thermal insulation coating. TGA® Poly-Asparagus Metal High-efficiency Thermal Insulation and Energy-saving Anticorrosion Coating

is a new high-tech product with the functions of waterproof, anticorrosion, thermal insulation and decoration, which is energy-saving, environmentally-friendly,

safe and economical, and overcomes the safety problems such as fire, hollowing, cracking, falling off and so on caused by multi-layer thick materials and

complicated construction procedures in traditional thermal insulation methods.

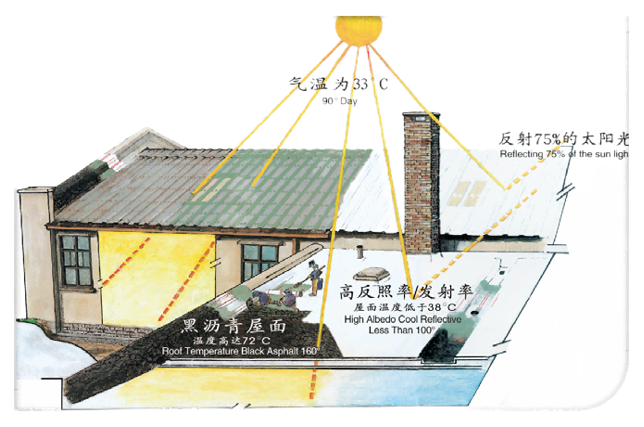

3、Energy Saving Effect

4、Product Performance

☆ Good thermal insulation.

The coating can reflect light and heat to achieve the effect of cooling and energy saving, and the temperature difference of heat insulation is as high

as 17 ~ 25℃; Year-round guarantee: in addition, it can reduce the radiation energy or solar heat energy reflected by heat conduction microspheres,and effectively

prevent theradiation heat of buildings during summer and winter. Saving and reducing energy consumption, it is the most ideal thermal insulator for all

sidewalls and roofs;

☆ Excellent physical properties.

The coating film is tough, dense, plump and bright, without discoloration, yellowing, pulverization, aging resistance and salt spray resistance for 4000 hours;

☆ Excellent protection.

Excellent waterproof, impermeability, wear resistance and impact resistance, excellent chemical medium resistance, such as acid, alkali, salt, etc.

☆ Strong adhesion.

The substrate can be firmly attached and is not easy to fall off, and the cathode peeling resistance distance is less than 9.5mm;

☆ Safety and environmental protection

No heavy metal, non-flammable, non-toxic, environmentally friendly;

☆ Durable

Excellent durability reduces the lifetime maintenance cost and prolongs the service life of the spraying structure;

5、Project Case

Outer wall of storage tank in chemical plant Container reconstruction house Renovation of Commercial Aircraft Roof

6、Product Health And Safety Information

Please refer to the latest version of product technical safety technical instruction manual (MSDS) of TGA company for information and suggestions on product operation,

storage and disposal. It includes product physical characteristics, ecological, toxicological data and other relevant safety information data.

7、Principle Of Good Gaith

TGA promises that all the product data listed above are obtained by testing in relevant laboratories according to corresponding standards. During the test, the

relevant data will be slightly different due to the different test environment and methods. Therefore, TGA company advises customers to do experimental demonstration

before using the product. Except for the product quality itself, TGA Company assumes no responsibility and reserves the right to adjust and update the above data

without prior notice.

简体中文

简体中文 English

English