Energy-Saving Thermal Insulation CoatingEnergy-Saving Thermal Insulation Coating

Active Practitioner Of Green Environmental Protection And Energy-saving Products

Industrial Waterborne Nano Thermal Insulation Coatings (Carbon Reduction and Consumption Reduction)

★Waterproof and Anticorrosion ★Wear protection ★Anti-fouling Self-cleaning

★Heat Insulating ★Fire and Flame Retardan

TGA@Industrial Waterborne Nano Thermal Insulation Coatings (Carbon Reduction and Consumption Reduction)

1、Thernal Insulation

TGA® water-based nano thermal insulation medium coat is a kind of water-based polyurethane nano ceramic microbeads and aerogel material, which has the

thermal insulation function with low thermal conductivity. The molecular vibration thermal conductivity and convection thermal conductivity of the pore wall in the

coating film are almost close to 0. If 2-3mm thermal insulation medium coat is applied to the surface of pipeline or oil storage tank with high temperature, the energy

loss can be reduced, the personnel can be prevented from being scalded, and the industrial pain point that traditional thermal insulation materials cannot achieve

complex structure can be solved at the same time. At present, this product has been applied in many fields such as ships, rail transit, petroleum and petrochemical,

storage tanks, external surfaces of high-temperature pipelines, and internal and external walls of buildings, and can also be used as sound-absorbing materials in

transportation equipment, ship engine rooms, equipment rooms and so on. And get high praise from customers in various industries.

2、Product Performance

★Precise bonding with the substrate,High pressure spraying on external surface of any shape.Avoiding corrode.

★Energy saving,Funding saving,Employees protecting,Safer working environment.

★Applied to outdoor pipelines,Reducing thermal radiation,Avoiding/reducing condensation on the surface of low-temperature objects.

★Applied to outdoor pressure vessels or pipelines,Minimizing the influence of sunlight exposure.

★Excellent durability,Low cost maintenance,longer the service life of the structure.

★Safe coating,environment-friendly,pollution-free, free of organic volatiles and heavy metals.

3. Defects of traditional thermal insulation materials

Disadvantages of this kind of process:

Disadvantages of this kind of process:

1. The material usually absorbs water, which leads to corrosion under the insulation layer, which brings significant security risks to the operation of equipment and facilities;

2, the process is complex, the cost is high, the service period is short, and the maintenance and renovation cost is high;

3, the construction is poor, and it cannot provide thermal insulation protection for complex structures;4, can't give the insulation layer a variety of colors and beautiful appearance.

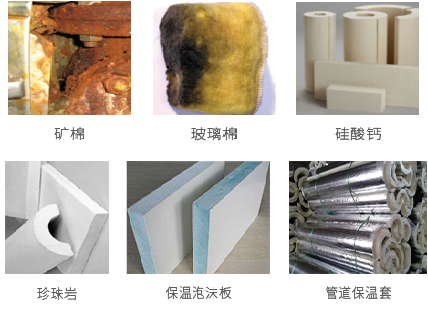

4、Advantages Of TGA Coating

TGA® water-based nano thermal insulation medium coat has three thermal resistance conditions: conduction, convection and radiation, of which the most important

function is to inhibit heat conduction. The aerogel and nano-ceramic microbeads contained in it have low thermal conductivity, with a thermal conductivity of 0.03

w/m*k, which prevents the conduction of heat. The thicker the coating, the better the thermal insulation effect and the greater the temperature difference.

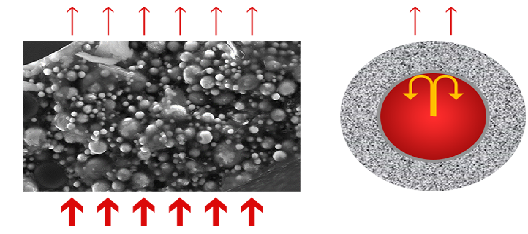

In the 1.2-meter experimental test pipeline, the heat resistance of the substrate surface using this product is 25-30% higher than that of the steel surface without

thermal insulation coating. The test results of film thickness and substrate surface temperature are compared with the improved efficiency of bare steel. At the

same time, the strength of nano-ceramic beads is high, which makes them suitable for high-pressure airless spraying without fragmentation, and increases the impact

resistance of coatings; It can be used on complex nozzle, flange and other external surfaces of any shape.

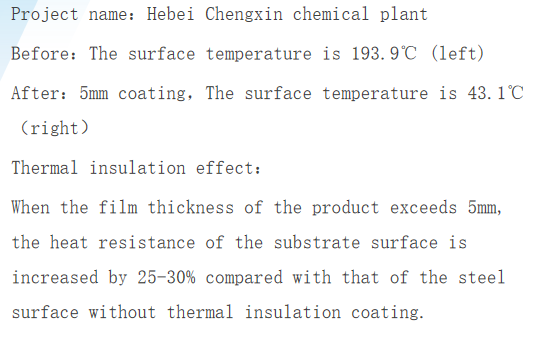

5、Project Case

6、Product Health And Safety Information

Please refer to the latest version of product technical safety technical instruction manual (MSDS) of TGA company for information and suggestions on product operation,

storage and disposal. It includes product physical characteristics, ecological, toxicological data and other relevant safety information data.

7、Principle Of Good Gaith

TGA promises that all the product data listed above are obtained by testing in relevant laboratories according to corresponding standards. During the test, the

relevant data will be slightly different due to the different test environment and methods. Therefore, TGA company advises customers to do experimental demonstration

before using the product. Except for the product quality itself, TGA Company assumes no responsibility and reserves the right to adjust and update the above data

without prior notice.

简体中文

简体中文 English

English