Anti-corrosion Protective Coatings For BridgesAnti-corrosion Protective Coatings For Bridges

TGA9531 Waterproof Antisepsis Coatings

TGA9531 Waterproof Antisepsis Coatings

【Product Manual】

Product Description

TGA9531 is formed by the reaction polymerization of polyaspartic acid ester and polyisocyanate. Because polyaspartic acid ester is aliphatic hindered secondary amine,

and the curing component is aliphatic polyisocyanate, the film formed has high light and color retention characteristics, and the bottom, middle and surface are integrated,

which is suitable for long-term outdoor use. When secondary amine groups react with isocyanate groups, a high cross-linking density and interpenetrating polymer chain

network structure is formed, which also makes this product have good physical and chemical characteristics.

Product Features And Advantages

1.High solid and low viscosity, good leveling property, tough and dense coating, plump and bright, and bright color.

2.Strong adhesion to the base, and good compatibility with polyurethane, epoxy and other materials.

3.High hardness, good scratch resistance and stain resistance.

4.Excellent wear resistance and impact resistance.

5.Excellent corrosion resistance and chemical medium resistance, such as acid, alkali, salt and so on.

6.No discoloration, yellowing, pulverization, aging resistance, excellent weather resistance and light and color retention.

7.It can be directly applied to surface coating of metal surface (DTM).

8.This product does not contain benzene solvents and lead elements, and is environmentally friendly.

Recommended Use

Corrosion protection and protection of steel structures, storage tanks, containers, valves, natural gas pipelines, frames, axles, shelves, tank cars, swimming pools, sewage pools,

various wear-resistant floor surfaces, terrazzo surfaces, chemical cofferdams and other fields.

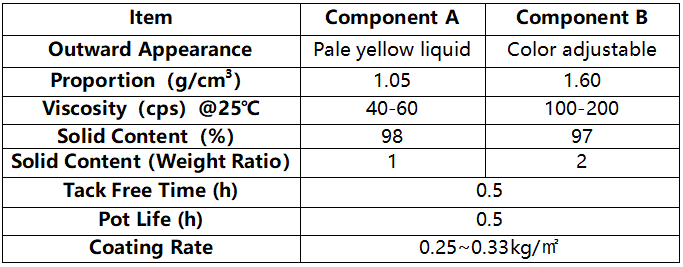

Product Information

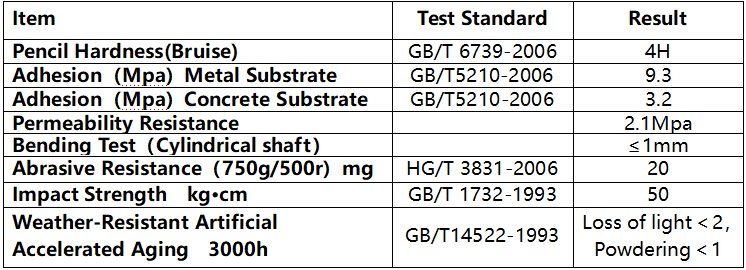

Physical Properties Of Product

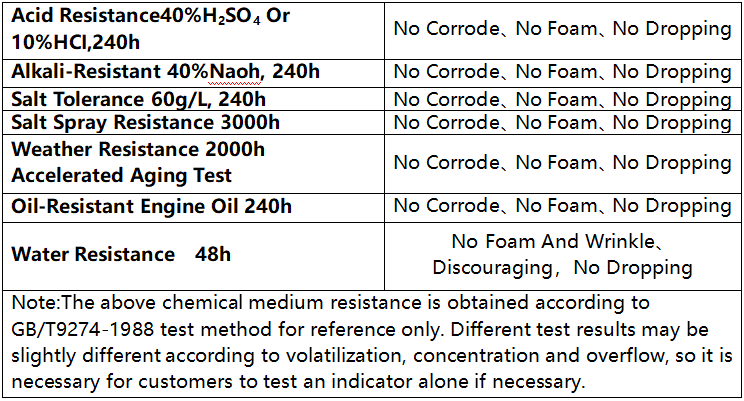

Product Corrosion-Resistant Medium

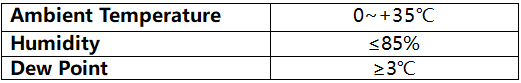

Product Construction Environment

Method Of Application

Hand brushing and rolling brush

Two-component variable ratio high-pressure airless spraying machine

Recommended dry film thickness: 200-500μm m.

Coating interval: minimum 0.5h and maximum 24h.

Points For Attention

Before use, mix the component B thoroughly and evenly.

According to the requirements, the mixture ratio is adjusted, and how much is used, and it is used

after being stirred evenly. The prepared coating is used up within 30 minutes.

After painting, the raw materials in the packaging barrel must be tightly covered to prevent moisture absorption.

Keep it dry and clean during construction, and do not contact with water, alcohol, acid, alkali, etc.

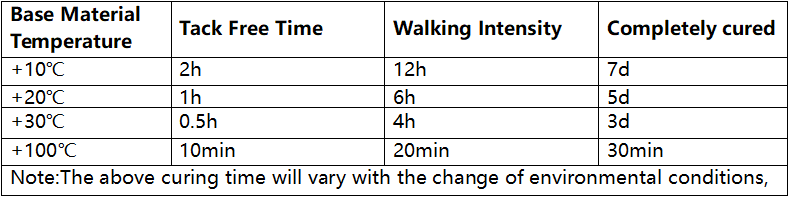

Curing Time

Product Shelf Life

1. Storage environment temperature: 5℃-35℃

2. The shelf life of the product shall start from the production date and be in the unopened state.

3. component A: 10 months; component B: 10 months.

4. Make sure that the product packaging is well sealed.

5. Store in a cool and ventilated environment to avoid direct sunlight.

6. Packaging: 9 kg/barrel for component A and 21 kg/barrel for component B.

Product Health And Safety Information

Please refer to the latest version of the product technical safety technical instruction manual (MSDS) of Aochang Company for information and suggestions on product

operation, storage and disposal. It includes product physical characteristics, ecological, toxicological data and other related safety information data.

Statement of good faith

AoChang promises that all the product data listed above are obtained by testing in relevant laboratories according to corresponding standards. During the test, the

relevant data will be slightly different due to the different test environment and methods. Therefore, AoChang company advises customers to do experimental demonstration

before using the product. Except for the product quality itself, AoChang Company assumes no responsibility and reserves the right to adjust and update the above data

without prior notice.

简体中文

简体中文 English

English